A small sanitary napkin solves a big problem for girls. In fact, it contains quite high technological content.

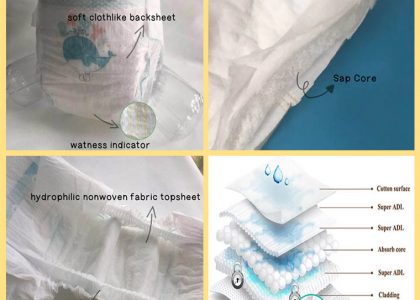

Women’s sanitary products, that is, women’s menstrual sanitary products, can be further divided into four major categories: female sanitary napkins, sanitary pads, tampons and sanitary cups according to the functions and forms of different products (the latter two categories of products are currently recognized in the country The degree of popularity and acceptance is still low, and it is mainly used by European and American women). In terms of structure, sanitary napkins can be divided into top layer, absorbent core, bottom layer and coating layer.

Top layer: in direct contact with the user’s skin, its main function is to allow liquid to penetrate quickly and effectively prevent back seepage, keeping the surface of the sanitary napkin dry. Sanitary napkins can be divided into three categories according to the surface material: ①Cotton-soft sanitary napkins: refer to sanitary napkins whose surface layer is made of various non-woven materials (mainly spunbond and hot-air non-woven fabrics) ; ②Dry mesh sanitary napkin: refers to the sanitary napkin whose surface layer is made of various perforated films; ③Pure cotton sanitary napkin: refers to the sanitary napkin whose surface layer is made of pure cotton material .

Absorbent core: used to absorb and store liquids, mainly composed of polymer absorbent resin (SAP), fluff pulp, absorbent paper and wood pulp.

Bottom layer: used to prevent liquid leakage. It is mainly made of special polyethylene (PE) plastic film as the base material. It is waterproof and breathable. Currently, some high-end products use a composite material composed of PE film and non-woven fabric as the bottom layer. . In addition, this layer also has hot melt adhesive (mainly used for sticking and fixing the product during use) and release paper (commonly known as silicone paper or release paper, which protects the viscosity of the hot melt adhesive before use).

Coating layer: commonly known as quick and easy packaging, it mainly uses non-woven fabric or PE cast film as the material. In order to enhance the visual effect of the product, the coating layer is usually added with various bright colors and printed with exquisite patterns.

PE cast film is a controllable stretch and controllable orientation cast extrusion film produced from polyethylene (LDPE, LLDPE, HDPE), breathable resin, color masterbatch and other raw materials through melt casting and quenching. Its characteristics are: The production speed is fast and the output is high. The moisture permeability, transparency, gloss, softness, and thickness uniformity of the film are all excellent. At the same time, because it is a flat-extruded film, subsequent processes such as embossing, printing, lamination, etc. are extremely convenient. , so it is widely used in daily necessities, medical supplies and other fields.